At BlueScope Steel, we are committed to continually improving our environmental footprint.

COMMITTED TO IMPROVING OUR ENVIRONMENTAL PERFORMANCE

At BlueScope Steel, we are committed to continually improving our environmental footprint.

We will achieve this through:

- Fostering and promoting a continuous improvement culture

- Capital investment to maintain and improve our equipment and facilities

- Robust systems to manage our responsibilities

Even in difficult times, our commitment to caring for the environment remains strong and the performance of a number of BlueScope sites has been recognised by external bodies:

- ISO 14001 - Many BlueScope Steel sites continue certification.

- World Steel Association – Continued membership of the Climate Action program as participants in the worldsteel CO2 data collection program.

- Sydney Water - Port Kembla Steelworks awarded Largest Volume Reduction based on water savings achieved from plant improvements.

- Malaysian Prime Minister's Hibiscus Awards - Lysaght Kuching awarded the State Award and the Notable Achievement Award for Environmental Performance.

- Krakatau Industrial Estate Cilegon (KIEC) - BSI Cilegon won the inaugural award for Plant with Cleanest Environment.

- American Metal Market Awards - North Star BlueScope Steel nominated as a finalist for the Steel Excellence Environmental Stewardship category.

- New Zealand Institution of Professional Engineers Environmental Awards - New Zealand Steel received a Merit Award for the new Taharoa fish pass.

We manage our environmental risks and impacts through the use of a framework we call LAWWNE, which seeks to:

- Reduce our environmental impact on Land, Air, and Water

- Reduce generation of Waste and Noise

- Minimise our use of Energy and the generation of Greenhouse Gas Emissions

Through the use of this framework we also seek to conserve scarce resources by reusing and recycling material.

We are committed to monitoring and publicly reporting on our progress. Public reporting takes place through our participation in independent external reporting initiatives, such as Australian National Greenhouse and Energy Reporting and the National Pollutant Inventory, and through initiatives such as this Community, Safety and Environment (CSE) Report.

This Report provides comprehensive information about BlueScope Steel and the environment, including governance and policy arrangements, and performance measures. The Report is structured around our LAWWNE framework.

Restructure of Australian Operations

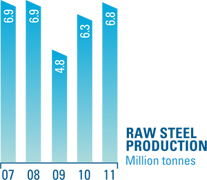

On 22 August 2011, BlueScope Steel announced a major restructure of its Australian operations.

The restructure, which involves a reduction in steel manufacturing capacity from 5.3 million tonnes per annum to 2.6 million tonnes per annum, includes shutting down a variety of facilities including the No. 6 Blast Furnace at Port Kembla and the Western Port Hot Strip Mill. This will better align Australian steelmaking production with Australian domestic demand and see BlueScope Steel exit the Australian export business.

A corresponding reduction in the environmental footprint will accompany the significantly reduced production capacity at both Port Kembla Steelworks and Western Port.