Zero Emissions from Process Disturbances

For many manufacturing activities throughout the world, process disturbances have the potential to lead to air emissions. Throughout decades of operation, BlueScope Steel has been reducing the number of process disturbances leading to air emissions, as well as the extent of emissions when process disturbances do occur. The Company aspires to extend this improvement record in order to eliminate all air emissions from process disturbances.

Continually Reducing Air Emissions

Clean air is essential to all living organisms. BlueScope Steel is committed to improving air quality in the communities where we operate and aspires to continually lower all types of emissions to air.

Current controls

BlueScope Steel has installed control mechanisms to reduce emissions at many facilities, including:

- Baghouse / filtration systems

- Chemical treatment

- Thermal oxidisation

- Scrubber systems

- Dust suppression

The Company extensively monitors emissions at its operations, both on and off site, to understand community impact, identify improvement  opportunities, and maintain compliance with regulatory limits,

opportunities, and maintain compliance with regulatory limits,

A number of facilities are required to report air emission data to regulators. Depending on the regulatory program, emission data may be published.

Performance

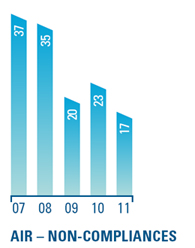

Through diligent operational management and engineering, BlueScope Steel has successfully reduced the number of non-compliances relating to air by more than 50 per cent over the past four years. During FY2011, there were 17 air related non-compliances reported to regulators, and no significant air related incidents.

Three key pollutants have been selected to monitor and report across the Company, Particulate Matter less than 10 microns (PM10), Oxides of Nitrogen (NOx) and Sulphur Dioxide (SO2). Emissions of these pollutants are either measured at the source or estimated based on emission factors and operating data. There were no significant changes in emissions during FY2011.

The GFC and No. 5 Blast Furnace Reline affected production and thus emission levels during FY2009. From FY2010, fugitive dust emission estimates from vehicle movements and stockpiles at the Port Kembla Steelworks were included in the PM10 data set. Reductions in SO2 emissions have been achieved at the Port Kembla Sinter Plant via operation of the Gypsum Plant.

The major restructure of the Australian operations during the later part of 2011 will have a major impact on emission levels.